Engineering Resources

Research Library

The top resource for free research, white papers, reports, case studies, magazines, and eBooks.

Close

- Engineering

- Broadcast Engineering

- Chemical

- Civil and Environmental

- Control Engineering

- Design Engineering

- Electrical Engineering

- GIS

- General Engineering

- Industrial Engineering

- Manufacturing Engineering

- Materials Science

- Mechanical Engineering

- Medical Devices

- Photonics

- Power Engineering

- Process Engineering

- Test and Measurement

- Agriculture

- Automotive

- Career

- Construction

- Education

- Engineering

- Broadcast Engineering

- Chemical

- Civil and Environmental

- Control Engineering

- Design Engineering

- Electrical Engineering

- GIS

- General Engineering

- Industrial Engineering

- Manufacturing Engineering

- Materials Science

- Mechanical Engineering

- Medical Devices

- Photonics

- Power Engineering

- Process Engineering

- Test and Measurement

- Finance

- Food and Beverage

- Government

- Healthcare and Medical

- Human Resources

- Information Technology

- Data Infrastructure

- Data Tools

- Desktops, Laptops and OS

- Chip Sets

- Collaboration Tools

- Desktop Systems - PCs

- Email Client

- Embedded Systems

- Hardware and Periferals

- Laptops

- Linux - Open Source

- Mac OS

- Memory Components

- Mobile Devices

- Presentation Software

- Processors

- Spreadsheets

- Thin Clients

- Upgrades and Migration

- Windows 7

- Windows Vista

- Windows XP

- Word Processing

- Workstations

- Enterprise Applications

- IT Infrastructure

- IT Management

- Networking and Communications

- Bluetooth

- DSL

- GPS

- GSM

- Industry Standard Protocols

- LAN - WAN

- Management

- Mobile - Wireless Communications

- Network

- Network Administration

- Network Design

- Network Disaster Recovery

- Network Interface Cards

- Network Operating Systems

- PBX

- RFID

- Scalability

- TCP - IP

- Telecom Hardware

- Telecom Regulation

- Telecom Services

- Telephony Architecture

- Unified Communications

- VPNs

- VoIP - IP Telephony

- Voice Mail

- WAP

- Wi-Fi (802.11)

- WiMAX (802.16)

- Wide Area Networks (WAN)

- Wireless Internet

- Wireless LAN

- Security

- Servers and Server OS

- Software and Web Development

- .Net Framework

- ASPs

- Application Development

- Application Servers

- Collaboration

- Component-Based

- Content Management

- E-Commerce - E-Business

- Enterprise Applications

- HTML

- IM

- IP Technologies

- Integration

- Internet

- Intranet

- J2EE

- Java

- Middleware

- Open Source

- Programming Languages

- Quality Assurance

- SAAS

- Service-Oriented Architecture (SOA)

- Software Engineering

- Software and Development

- Web Design

- Web Design and Development

- Web Development and Technology

- XML

- Storage

- Life Sciences

- Lifestyle

- Management

- Manufacturing

- Marketing

- Meetings and Travel

- Multimedia

- Operations

- Retail

- Sales

- Trade/Professional Services

- Utility and Energy

- View All Topics

- Featured eBooks

- Trending Resources

- New Resources

- Promote Your Content

- Partnership Opportunities

- Get RSS Updates

- About TradePub.com

- FAQ

- Contact Us

Share Your Content with Us

on TradePub.com for readers like you. LEARN MORE

Request Your Free White Paper Now:

"Reducing maintenance costs through component lubrication"

Save time and money by making one simple change

One of the most expensive aspects to consider in automation is the cost of machine downtime. Downtime costs can range from $1,000 to $10,000 a minute depending on the application, which over the course of the year could lead to costs of over $3.9 million. Being able to reduce or even eliminate downtime altogether is therefore one of the most effective ways to save money when implementing automation. Read on to learn about possibly the easiest way to do so: eliminating bearing lubrication.

What you will learn:

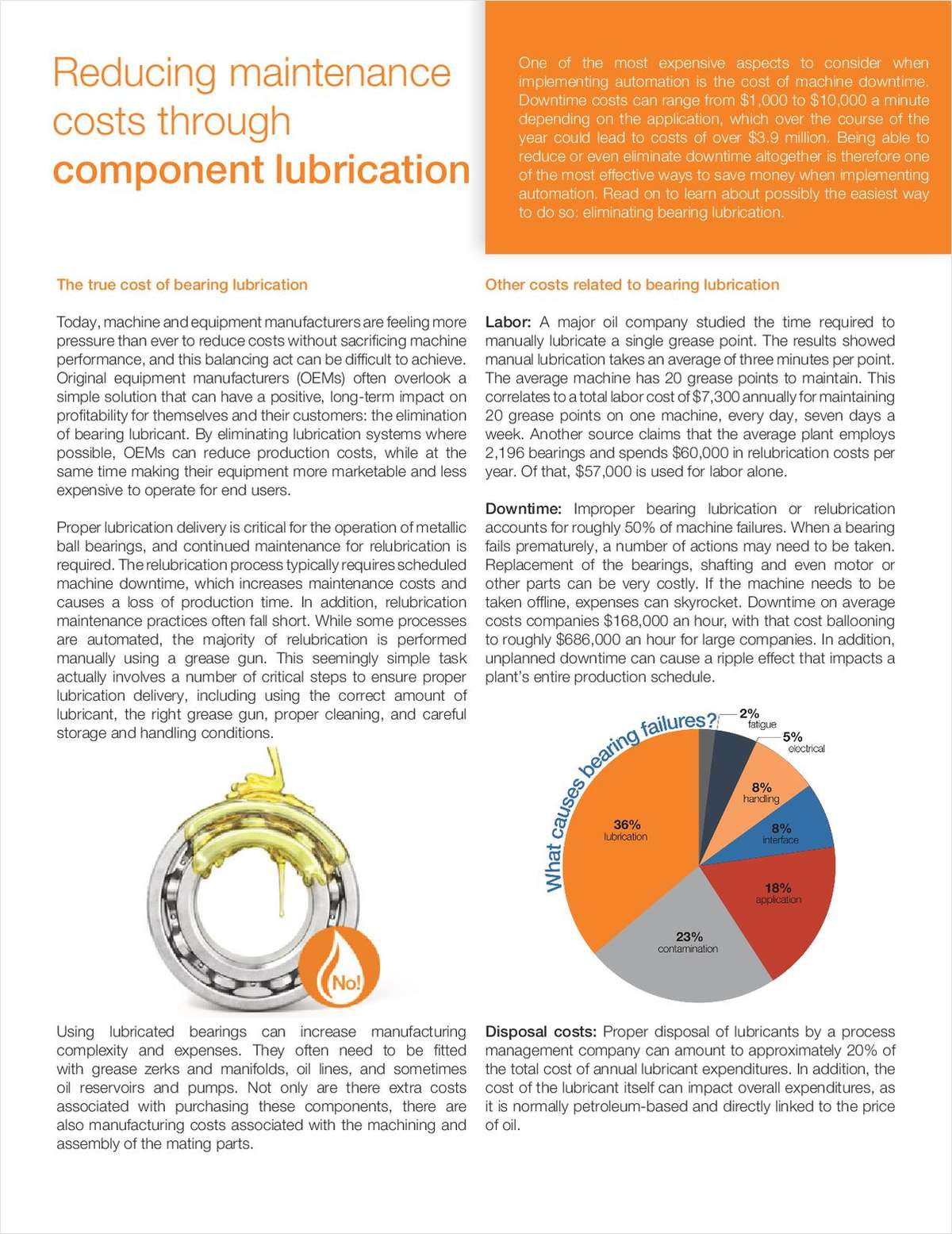

- The leading causes of bearing failure

- The average cost of downtime due to bearing failure

- Grease-free alternatives to standard bearings

Offered Free by: igus

See All Resources from: igus

Recommended for Professionals Like You: